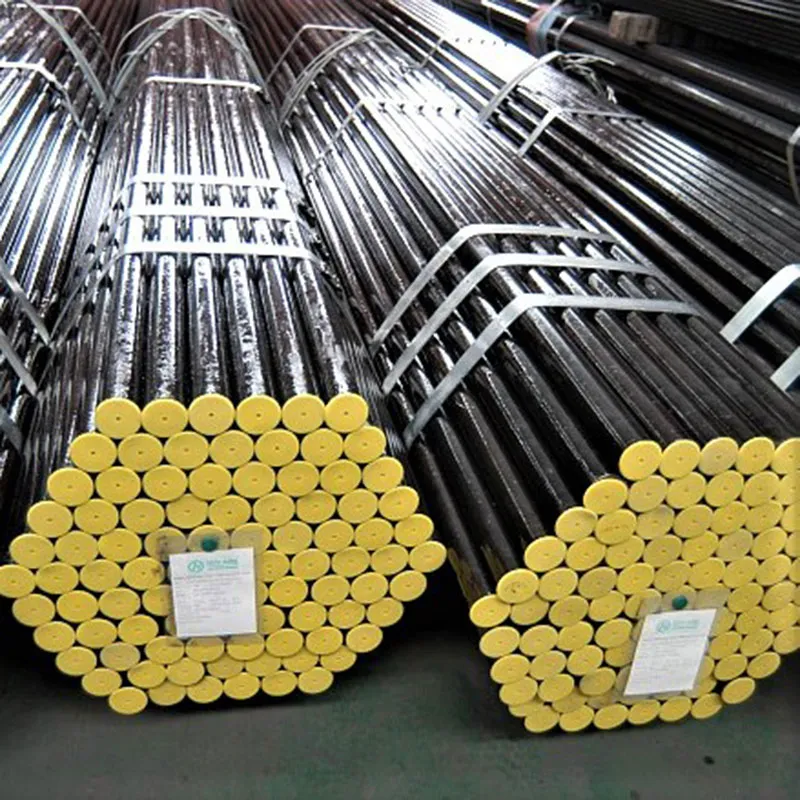

Seamless Line Pipes

Seamless Line Pipes are high-performance steel pipes manufactured without welding seams, ensuring superior strength, pressure resistance, and reliability for critical fluid transportation applications. These pipes are widely used in oil & gas, petrochemical, and water transmission industries due to their excellent structural integrity and corrosion resistance.

Specifications

Type: Seamless (SMLS)

Size Range:

Outer Diameter (OD): 1/2" to 24" (DN15 to DN600)

Wall Thickness: SCH 10 to SCH XXS (customizable)

Length: 5.8m,6m to 12.5m (or as per customer requirements)

Pressure Rating: API 5L PSL1 & PSL2, up to X80 grade

Material & Grades

Common Materials:

Carbon Steel: ASTM A106 Gr. B, API 5L Gr. B/X42/X52/X60/X65/X70/X80

Alloy Steel: ASTM A335 P11/P22/P91 (for high-temperature service)

Stainless Steel: ASTM A312 TP304/316 (corrosive environments)

Standards Compliance:API 5L, ASTM A106, ASTM A53, ASME B36.10, ISO 3183

Features & Performance

High Strength & Durability – No welded seams eliminate weak points, ideal for high-pressure applications.

Superior Corrosion Resistance – Suitable for harsh environments (offshore, sour gas, acidic fluids).

Excellent Dimensional Accuracy – Smooth internal surface reduces friction and improves flow efficiency.

Pressure & Temperature Resistance – Handles extreme conditions (up to 1000°C for alloy grades).

Leak-Proof & Reliable – No risk of weld defects, ensuring long-term safety.

Applications

Oil & Gas Industry:Crude oil & natural gas transmission (onshore/offshore pipelines).

Gathering lines, well casings, and refinery piping.

Petrochemical Plants:High-pressure steam, chemical, and hydrocarbon transport.

Water & Utilities:High-pressure water mains, sewage systems.

Power Generation:Boiler tubes, heat exchangers (ASTM A335 alloy pipes).

Testing & Certifications

Non-Destructive Testing (NDT): Ultrasonic (UT), Hydrostatic, Eddy Current.

Mechanical Tests: Tensile strength, hardness, impact (Charpy V-notch).

Certifications: API 5L, ISO 9001, PED 2014/68/EU, NACE MR0175 (for sour service).

Packaging & Delivery

Packaging: Plastic caps, bundled with steel strips, woven bags or wooden crates for protection.

Delivery: Standard 20ft/40ft containers or bulk shipment (OD ≥ 16" shipped individually).