|

Item |

Details |

|

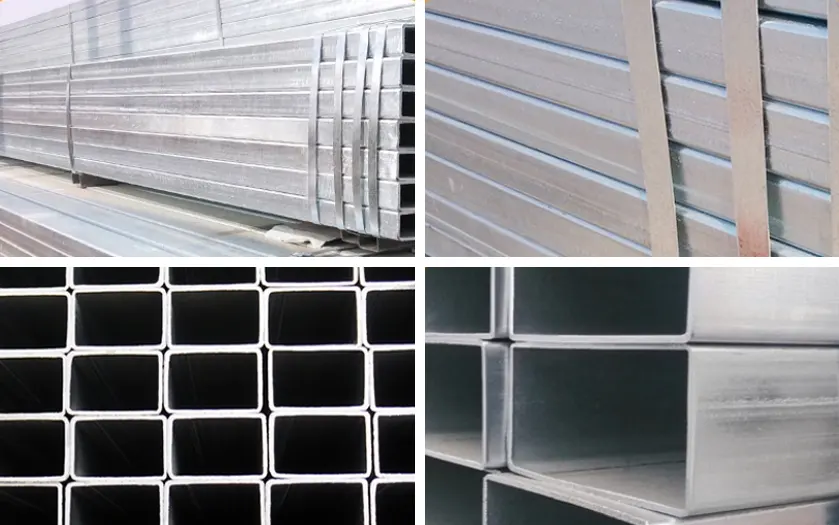

Product Name |

Galvanized Square Tubes |

|

Shape |

Square cross-section |

|

Size Range |

10×10mm to 150×150mm (custom sizes available) |

|

Wall Thickness |

0.8mm to 6.0mm |

|

Length |

Standard 6m; custom lengths up to 12m |

|

Galvanization Type |

Hot-dip galvanized (zinc coating: 40-275 g/m²), electro-galvanized |

|

Base Material & Grades |

Carbon steel (Q195, Q235, SS400, ASTM A36) |

|

Zinc Coating Standards |

ASTM A653, EN 10346, JIS G3302 |

1. Raw Material Preparation:

Inspection and cutting of high-quality carbon steel strips (Q195/Q235/SS400/ASTM A36) to required dimensions.

2. Forming:

Cold-rolling steel strips into square cross-sections using precision forming equipment, ensuring uniform shape and dimensions.

3. Welding:

Electric resistance welding (ERW) to create seamless, durable longitudinal seams for structural stability.

4. Galvanization:

Hot-dip galvanizing (submerging in molten zinc) or electro-galvanizing to form a protective zinc layer, enhancing corrosion resistance.

5. Post-Treatment:

Cleaning and inspection of the zinc coating to ensure uniformity and adherence to standards (40-275 g/m²).

6. Cutting & Finishing:

Cutting to standard 6m lengths or custom sizes, with deburring for smooth edges.

7. Quality Inspection:

Dimensional checks, coating thickness tests, and corrosion resistance verification.

8. Warehousing:

Stocking in our factory’s 20,000-ton inventory for immediate delivery.

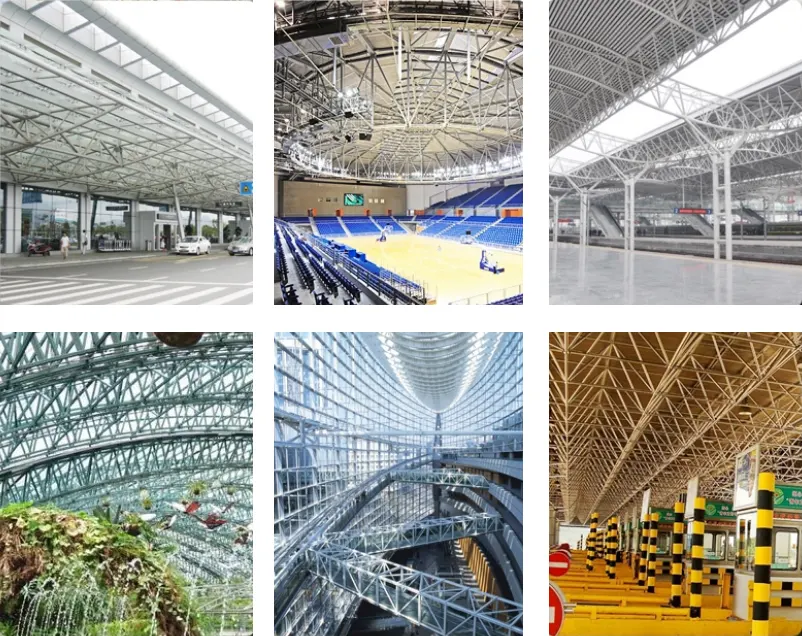

Superior Corrosion Resistance:

Zinc coating prevents rust and deterioration, adapting to Middle East salt spray, African humidity, and Southeast Asia rainfall.

High Strength & Durability:

Carbon steel base ensures reliable load-bearing capacity for structural applications like scaffolding and greenhouse frames.

Easy Fabrication:

Can be welded, drilled, or cut on-site, fitting diverse project requirements across regions.

Weather Resistance:

Performs well in extreme temperatures (55°C+ desert heat, tropical rains) and harsh environments.

Aesthetic Appeal:

Uniform zinc coating delivers a smooth surface, suitable for decorative and visible applications.

Adequate Inventory & Fast Delivery:

20,000-ton stock enables 5-7 day delivery for standard orders, meeting urgent project timelines.

Our Galvanized Square Tubes comply with global and regional standards for seamless project approval:

|

Application |

Recommended Specification |

Key Features |

Target Region |

|

Greenhouse Frames |

20×20mm~50×50mm, WT 1.2-2.5mm, hot-dip galvanized |

Corrosion-resistant, lightweight |

Africa, Southeast Asia |

|

Construction Fencing/Scaffolding |

30×30mm~80×80mm, WT 2.0-4.0mm, hot-dip galvanized |

High strength, weather-resistant |

All Regions |

|

Machinery Frames |

40×40mm~100×100mm, WT 3.0-5.0mm, hot-dip galvanized |

Durable, easy to weld |

Middle East, Southeast Asia |

|

Handrails/Signage |

25×25mm~60×60mm, WT 1.5-3.0mm, electro-galvanized |

Smooth finish, aesthetic appeal |

All Regions |

|

Irrigation Systems |

30×30mm~70×70mm, WT 2.0-3.5mm, hot-dip galvanized |

Corrosion-resistant to water exposure |

Africa, Middle East |

|

Region |

Mandatory Documents |

Our Support |

|

Middle East (GCC) |

SASO Certificate, Certificate of Origin, MTC |

Assist with SASO application (3-5 working days) |

|

Africa (Nigeria/Kenya) |

SONCAP Certificate, Form M (Nigeria), CoO |

Support SONCAP registration and product testing |

|

Southeast Asia (Indonesia/Thailand) |

SNI/TIS Certificate, Customs Declaration, Coating Test Report |

Coordinate with local agents for hassle-free clearance |

1.Cold bending section steel surface can not have bubbles,cracks,inclusions and transverse stratification,wrinkle,buckle and so on. Allow slight pit,convex,indentation,scratch and pressure into the iron oxide,but is not greater than 10% of nominal wall thickness.

2.Surface defects allowed use grinding method to clear up,but after cleaning the thickness should be no less than minimum allowable thickness.

3.If have special requirements on surface quality of cold bending section steel ,determined by supply and demand.

RFQ Question: Can your hot-dip galvanized tubes resist Dubai’s coastal salt spray? What’s the delivery time?

Answer: Yes, our hot-dip galvanized square tubes (zinc coating ≥120g/m²) resist salt spray and 55°C desert heat.

RFQ Question: Need tubes for Kenya’s greenhouse project—will they withstand tropical rains? Delivery in 7 days possible?

Answer: Absolutely. Our 30×30mm~50×50mm hot-dip galvanized tubes resist tropical humidity and rains. We have sufficient stock, so 7-day delivery to Kenya is guaranteed.

RFQ Question: What’s the zinc coating thickness for tubes used in Saudi Arabia’s outdoor scaffolding? Lead time?

Answer: Our scaffolding tubes have a hot-dip galvanized coating of 150-275g/m², ideal for Saudi’s desert conditions. Stocked in 20,000-ton inventory, delivery takes 5-6 working days.

RFQ Question: Can you provide 100×100mm tubes for Indonesia’s machinery frames? Are they easy to weld?

Answer: Yes, our 100×100mm (WT 4.0mm) hot-dip galvanized tubes are perfect for machinery frames—easy to weld and corrosion-resistant to Indonesia’s humidity.

RFQ Question: Need 6m custom-length tubes for Nigeria’s rural school handrails—delivery time and durability?

Answer: We supply 6m custom-length tubes (25×25mm, WT 2.0mm) for handrails. Hot-dip galvanized for rain resistance, they’re durable for rural outdoor use.