|

Item |

Details |

|

Product Name |

Square Hollow Sections (SHS) |

|

Shape |

Square (equal sides) |

|

Size Range |

20×20mm to 400×400mm (custom sizes available) |

|

Wall Thickness |

1.2mm to 16mm (varies by application) |

|

Length |

Standard 6m or 12m; custom lengths upon request |

|

Tolerance |

Compliant with EN 10219, ASTM A500, JIS G3463 |

|

Material & Grades |

- Carbon Steel: S235JR, S355JR, ASTM A500 Gr B/C (general structural use)- Stainless Steel: 304, 316 (corrosion-resistant applications)- Alloy Steel (high-strength requirements) |

|

Surface Treatment |

Hot-dip galvanized (corrosion protection), painted, or powder-coated (aesthetics + extra protection) |

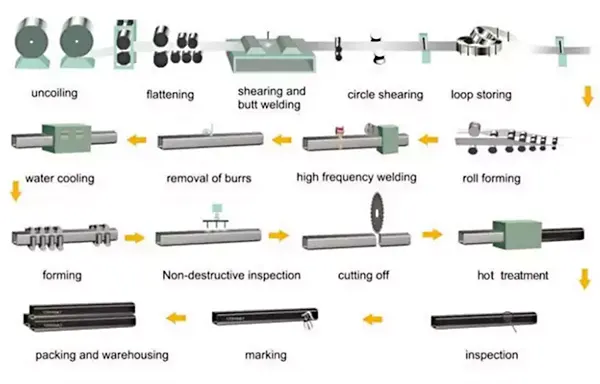

1. Raw Material Preparation:

Inspection and cutting of high-quality steel strips (carbon/stainless/alloy steel) to required dimensions.

2. Forming:

Cold-rolling steel strips into square cross-sections using precision forming equipment, ensuring uniform shape and dimensions.

3. Welding:

Submerged arc welding (SAW) or electric resistance welding (ERW) to create seamless, durable longitudinal seams—critical for Welded Structural pipe performance.

4. Sizing & Straightening:

Calibration to meet tolerance standards (EN 10219/ASTM A500) for roundness, straightness, and side equality.

5. Surface Treatment:

Application of hot-dip galvanizing, painting, or powder-coating based on regional environmental needs and customer requirements.

6. Customization (if required):

Pre-cutting, drilling holes, or adding special coatings (anti-rust, fire-resistant) for easy on-site assembly.

7. Quality Inspection:

Visual checks, dimensional measurements, and mechanical property testing (tensile, yield strength) to ensure compliance.

8. Packaging:

Bundling and protection before shipping.

High Strength-to-Weight Ratio:

Delivers robust load-bearing capacity while reducing overall construction weight—ideal for building construction steel pipe.

Easy Fabrication:

Flat surfaces enable easy alignment, welding, cutting, and assembly with other steel components, saving on-site time.

Corrosion Resistance:

Hot-dip galvanized or stainless steel options withstand Middle East salt spray, Southeast Asian humidity, and African tropical moisture.

Aesthetic Appeal:

Clean square shape suits visible structures like architectural façades, canopies, and street furniture.

Rigidity & Durability:

Uniform cross-section ensures stable performance in structural frameworks, bridges, and machinery frames.

Cost-Effective:

Efficient material use optimizes project budgets, fitting diverse regional construction needs.

Our SHS products comply with global and regional standards for seamless project approval:

|

Application |

Recommended Grade |

Key Specifications |

Target Region |

|

Building Frames/Columns |

ASTM A500 Gr B, S355JR |

50×50mm~300×300mm, WT 3-12mm |

All Regions |

|

Bridge Support Structures |

S355JR, Alloy Steel |

150×150mm~400×400mm, WT 8-16mm |

Middle East, West Asia |

|

Machinery Frames |

ASTM A500 Gr C, S235JR |

40×40mm~200×200mm, WT 2-8mm |

Southeast Asia, Africa |

|

Architectural Façades |

Stainless Steel 304/316, Powder-Coated Carbon Steel |

30×30mm~150×150mm, WT 1.2-5mm |

Middle East, Southeast Asia |

|

Infrastructure (Guardrails/Signage) |

S235JR, Hot-Dip Galvanized |

20×20mm~100×100mm, WT 1.2-4mm |

Africa, West Asia |

|

Region |

Mandatory Documents |

Our Support |

|

Middle East (GCC) |

SASO Certificate, Certificate of Origin, MTC |

Assist with SASO application (3-5 working days) |

|

West Asia (Iraq/Iran) |

Import License, Bilingual Test Reports, Compliance Letter |

Provide Persian/English documents for clearance |

|

Africa (Nigeria/Kenya) |

SONCAP Certificate, Form M (Nigeria), CoO |

Support SONCAP registration and product testing |

|

Southeast Asia (Indonesia/Thailand) |

SNI/TIS Certificate, Customs Declaration, WPQR |

Coordinate with local agents for hassle-free clearance |

RFQ Question: Can your galvanized SHS withstand Dubai’s desert heat, and what’s the delivery time?

Answer: Yes, our hot-dip galvanized SHS (ASTM A500 Gr B) resists 55°C+ desert temperatures and sand erosion.

RFQ Question: How to use SHS for Thailand’s coastal bridge—does it resist saltwater corrosion?

Answer: We recommend stainless steel 316 or 3PE-coated SHS for Thailand’s coastal bridges. They resist saltwater corrosion, meet TIS standards, and are easy to weld on-site.

RFQ Question: What’s the lead time for 50 tons of SHS (200×200mm) for Nigeria’s building project?

Answer: Lead time for 50 tons of SHS (200×200mm, ASTM A500 Gr B) is 10-15 working days. The product is SONCAP-approved, hot-dip galvanized for humidity resistance, and includes clearance support.

RFQ Question: Is your SHS suitable for Kenya’s rural school construction (outdoor use)?

Answer: Our hot-dip galvanized SHS (S235JR) is ideal for Kenya’s outdoor school construction. It resists tropical rains, is lightweight for easy transport to rural areas, and has a 8-year corrosion warranty.

RFQ Question: How to assemble SHS for Malaysia’s high-rise façade—do you provide guidelines?

Answer: We supply detailed English installation guides for SHS high-rise façades (including welding/joining tips). The powder-coated SHS resists Malaysia’s humidity, meets SNI standards, and delivers in 14-20 working days. On-site technical support is available.